In process industries, downtime can be costly and disruptive. Equipment failures, production halts, and inefficiencies can lead to significant losses. One tool that can help prevent downtime is RCA. But what exactly is RCA, and how does it work? This article explores how RCA can minimize disruptions and improve operational efficiency. With the right strategies, businesses can reduce downtime and boost productivity.

Uncovering Problems Before They Escalate

Unexpected breakdowns in process industries can lead to major disruptions. By thoroughly investigating operational issues early, companies can identify potential risks before they spiral out of control. Root Cause Analysis (RCA) is a critical method for pinpointing the source of these problems. This comprehensive approach ensures issues are addressed effectively, reducing their recurrence. Preventative measures not only save time but also eliminate unnecessary expenses caused by repeated breakdowns.

Enhancing Equipment Reliability

Well-maintained equipment is crucial for smooth operations. Regular inspections, combined with detailed diagnostics, help uncover hidden flaws in machinery before they cause serious issues. When breakdowns occur, digging deeper into the cause ensures accurate fixes that address the problem at its core. This approach not only solves current issues but also creates a long-term reliability framework. Improved machinery performance results in fewer interruptions, consistent output, and better overall operational efficiency.

Boosting Team Collaboration

Operational issues often require cross-departmental teamwork to resolve. Encouraging open communication among teams helps them address complex issues more efficiently and cohesively. Investigating the root causes of downtime fosters a collaborative culture, breaking down silos that can hinder progress. Teams learn to identify patterns, share insights, and develop innovative solutions to improve processes. By working together, they can implement robust strategies that minimize disruptions and increase workplace harmony.

Streamlining Processes for Efficiency

Complicated workflows can increase the risk of errors, delays, and operational inefficiencies. Analyzing recurring bottlenecks helps streamline these processes, making them more efficient and reliable. By addressing underlying inefficiencies, companies can eliminate redundancies that often go unnoticed. This ensures smoother operations, consistent production schedules, and a significant reduction in unexpected halts. Ultimately, organizations benefit from higher productivity, reduced waste, and enhanced profitability.

Building a Proactive Maintenance Culture

Preventative action is better than reactive solutions, especially in process industries where downtime can be costly. Developing a culture of proactive maintenance reduces the likelihood of operational issues and minimizes risks. By focusing on early detection through monitoring and analysis, teams can fix minor problems before they escalate into larger disruptions. This mindset ensures continuous operations, minimizes costs, and fosters a sense of responsibility among employees. A proactive approach safeguards resources and ensures long-term success.

Addressing Human Factors in Downtime Prevention

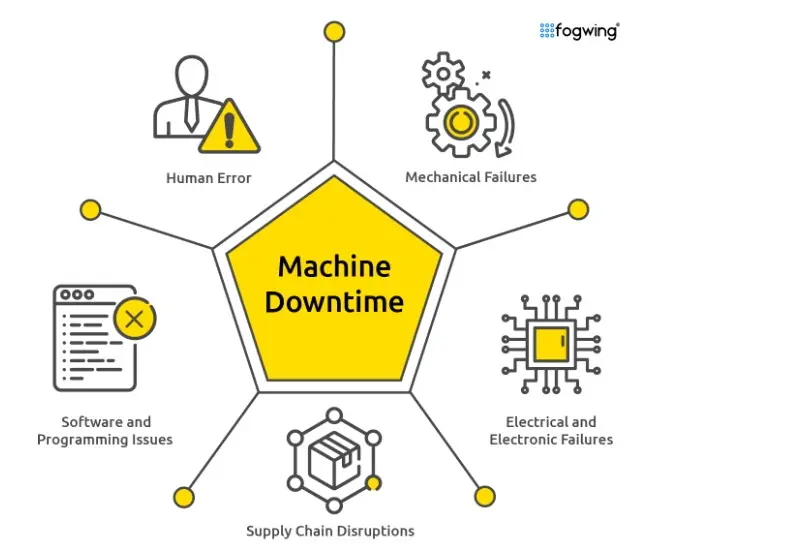

Human error can often be a significant factor contributing to downtime. Providing targeted training and fostering a culture of continuous learning equips employees with the skills to minimize mistakes. Recognizing and addressing behavioral patterns that lead to operational disruptions is essential. When employees are encouraged to take ownership of their roles, they become more vigilant and proactive. This reduces errors, improves workflows, and enhances overall operational stability.

The Role of Safety in Downtime Prevention

Safety is a key element in maintaining operational continuity. Addressing safety concerns early prevents accidents that might cause downtime and disrupt production. Root Cause Analysis uncovers hazards that could otherwise go unnoticed, enabling teams to take corrective actions promptly. Implementing safety measures alongside problem-solving techniques keeps the workplace secure and operations running smoothly. A strong focus on safety creates a resilient production environment and fosters employee confidence.

Effective problem-solving strategies are essential for minimizing downtime in process industries. Root Cause Analysis helps identify and resolve the core issues causing disruptions. By implementing this approach, companies can enhance efficiency, improve reliability, and foster teamwork. A proactive and safety-conscious culture ensures smoother operations, consistent output, and long-term productivity.

Also Read-Why Working with a Reliable Pneumatic Ball Valve Supplier Matters