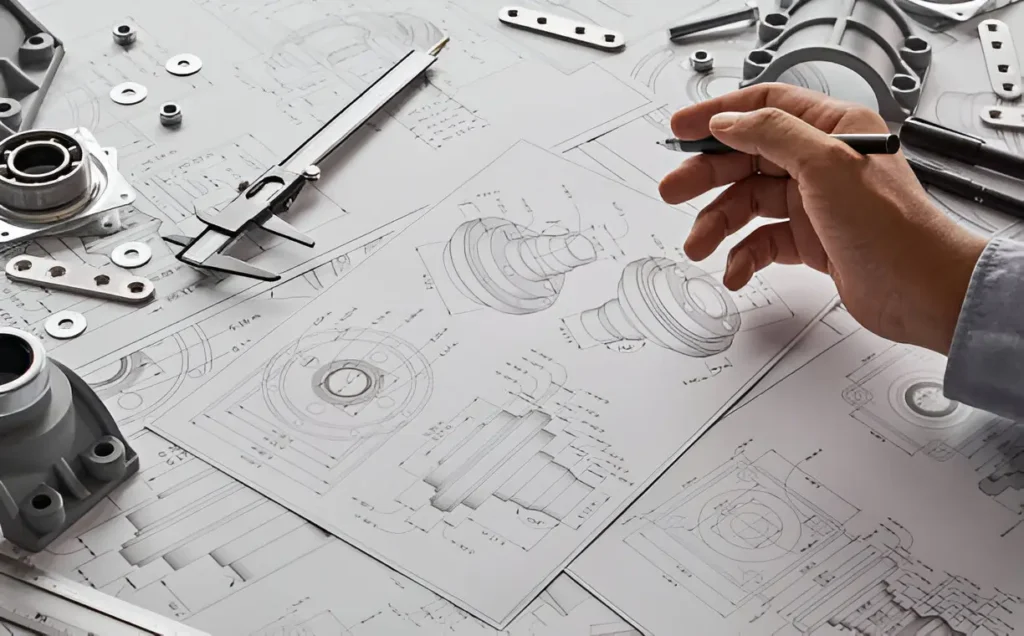

The world of prototyping and product development has undergone a profound transformation with the advent of precision tools. From laser cutting and CNC machining to 3D printing, these tools have made it easier than ever to bring innovative ideas to life. Engineers, designers, and manufacturers now have access to unmatched accuracy, efficiency, and customization options, paving the way for groundbreaking solutions across industries.

The Rise of Precision Tools in Product Development

Precision tools have become central to prototyping and manufacturing processes. Unlike traditional methods that often rely on extensive manual work and rudimentary machinery, today’s tools offer exceptional levels of control. This shift has made it possible to create complex designs with higher precision in a fraction of the time.

Among the notable advancements, laser cutting, CNC machining, and 3D printing stand out. These technologies have redefined how prototypes are developed, allowing for quicker iterations and more detailed models. Whether you’re working on a small-scale product or preparing for large-scale manufacturing, these tools significantly reduce the time and cost typically associated with traditional methods.

Key Precision Tools Transforming Prototyping

Laser Cutting

Laser cutting has redefined precision by offering unmatched accuracy and consistency. It works by using a high-powered laser beam to cut through various materials like metal, wood, and acrylic. The result is clean and precise cuts that prioritize both speed and quality.

This method is particularly beneficial for intricate designs and repeatable patterns. For example, startups and large manufacturers alike have turned to laser cutting to refine their prototypes accurately, ensuring each component is perfectly replicated. Whether you’re working on decorative elements or functional parts, laser cutting provides the flexibility needed to meet complex design requirements. Notably, there is growing interest in services such as laser cutting in Utah, as communities and businesses in the region increasingly adopt this technology.

CNC Machining

CNC (Computer Numerical Control) machining adds another layer of precision and reliability to modern product development. Through pre-programmed software, CNC machines can perform complex manufacturing tasks, such as cutting, drilling, and milling, with incredible accuracy. These machines are capable of handling an array of materials, including metals and plastics, making them a versatile tool for bringing designs to fruition.

CNC machining is ideal for prototypes where durability and exact measurements are crucial. It enables repeat production with minimal error, ensuring products not only meet but exceed industry standards. By employing CNC machining early in the design process, engineers can create prototypes that are closer to final products in both functionality and feel.

3D Printing

If there’s one tool that has democratized prototyping, it’s 3D printing. Unlike laser cutting or CNC machining, which removes material to create a shape, 3D printing builds objects layer by layer. This additive manufacturing process has made it easier for creators to experiment with shapes and materials that would otherwise be difficult or impossible to achieve.

3D printing’s affordability has also contributed to its popularity. It allows for rapid prototyping, where designers can test ideas quickly and make adjustments before settling on a final design. For custom products, limited-run items, and intricate geometries, 3D printing is an essential tool that leads product development into uncharted territory.

Benefits of Precision Tools in Prototyping

The real strength of precision tools lies in their ability to optimize the prototyping process. Here are some key benefits these tools bring to product development:

- Reduced Development Time

Prototypes that once required weeks to create can now be produced in mere hours or days. This efficiency allows teams to iterate faster, improving designs at a quicker pace. - Enhanced Accuracy

Precision tools eliminate much of the human error associated with traditional methods. Components are more consistent, ensuring a better fit and function. - Cost Effectiveness

By reducing material waste and streamlining production workflows, these tools lower overall manufacturing costs. Businesses can allocate resources to refining their product rather than managing inefficiencies. - Creative Freedom

Designers now have greater flexibility to experiment with ambitious ideas. Precision tools support intricate designs that were previously out of reach with manual manufacturing.

The Future of Precision Tools in Product Development

The trajectory of precision tools indicates an exciting future for innovation. Emerging technologies, such as AI-augmented design and advanced robotics, are expected to pair seamlessly with tools like laser cutters, CNC machines, and 3D printers. These advancements will make the prototyping process even more automated and intelligent.

Additionally, new materials are on the horizon. From biodegradable plastics to ultra-strong composites, these materials will expand what is possible in product design. Combined with the continual improvement in precision tools, product developers will be well-positioned to tackle exciting challenges in everything from healthcare and aerospace to consumer electronics.

Precision tools have eliminated many of the barriers traditionally associated with prototyping and product development. Thanks to technologies that enable faster, more accurate, and more cost-effective production processes, innovation is not just achievable but also scalable. The future holds even greater promise as precision tools continue to evolve, empowering businesses and creators to bring their visions to life with unparalleled ease.

Read more: Dealing with Burning or Shooting Pain in Your Legs